Tai Tin understands the importance of high-quality RF products that ensure long-term reliability and performance within network systems. To meet this demand, we uphold rigorous quality control standards throughout our manufacturing process, ensuring our products consistently meet industry benchmarks.

Our quality control measures include:

Certified Manufacturing

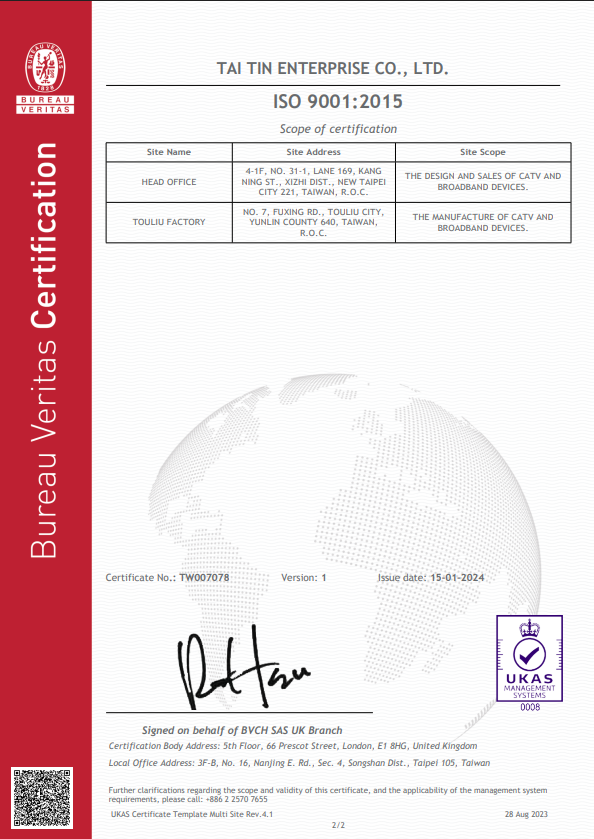

- ISO 9001:2015 certified manufacturing facility.

- Implementation of SQC (Statistical Quality Control) and AQL (Acceptance Quality Limit) procedures.

- Independent third-party audits and verification

Mechanical Testing

- Comprehensive mechanical performance evaluations.

- Class A EMI shielding testing (FCC 47 CFR 15 and EN50081-1).

- Pin clamp force testing (ANSI/SCTE 01 2015 and IEC 61169-24:2009).

Electrical Testing for RF Products

- Complete RF analysis and performance testing for all manufactured units.

- Inclusion of detailed RF test reports.

- Intermodulation testing (SCTE 145 2008).

- Hum modulation testing (ANSI/SCTE 16 2018).

Environmental Testing

- Salt spray and pressure testing (ANSI/SCTE 203 2014 and IEC 60068-2-52:2008).

- Shock and vibration testing (ANSI/SCTE 203 2014 and IEC 60068-2-64:2008).

- Temperature stress testing (ANSI/SCTE 203 2014 and IEC 60068-2-30:2008).

- 6kV surge protection testing (ANSI/SCTE 81 2018 and IEEE C62.41.2-2002).

Through these stringent quality control procedures, Tai Tin ensures that every RF product delivers superior performance, reliability, and compliance with industry standards.