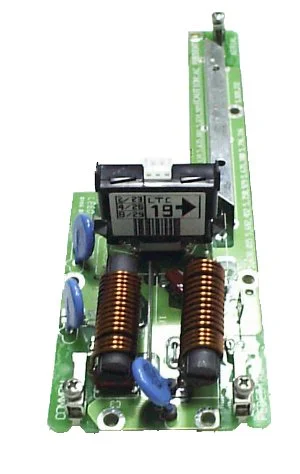

Tai Tin boasts extensive experience in the design and manufacturing of RF Printed Circuit Board (PCB) assemblies, offering a broad range of customized services tailored to meet the unique needs of RF applications. Our specialized expertise ensures high-quality performance and reliability in every RF PCB assembly we produce.

“Circuit Board Assembly and RF tuning Capability”

Key Benefits Include:

- RF Component Sourcing, Assembly & Final Product Testing – Comprehensive support for sourcing, assembly, and rigorous final testing for RF PCBs.

- EU RoHS 2 Compliance – Utilization of single-wave soldering equipment that meets RoHS 2 standards, ensuring environmentally-friendly production.

- Dedicated Quality Control – Multiple inspection stages throughout the process to ensure the highest quality standards for RF assemblies.

- Advanced Design & Drafting Software – Cutting-edge tools for precise RF PCB design and drafting, tailored for high-frequency applications.

- Complete SMT Assembly System – End-to-end Surface-Mount Technology (SMT) solutions for RF PCBs, including:

- Electronic Mounting Equipment – Specialized equipment designed for precise placement of RF components.

- Automatic Printing Press – Consistent and accurate printing for solder paste application on RF PCBs.

- Solid Paste Dispenser – Accurate paste dispensing for optimal solder joints in high-frequency circuits.

- Reflow Oven – High-performance ovens designed to properly solder delicate RF components.

Tai Tin’s RF PCB assembly services are designed to meet the unique challenges of high-frequency, high-performance applications, ensuring quality, precision, and reliability for every project.